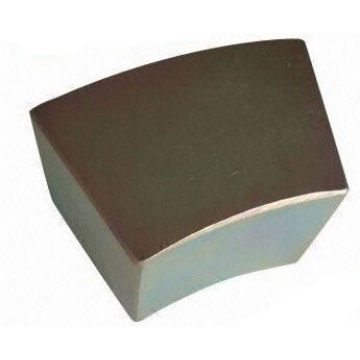

Sintered Segment Ceramic Magnet

| Payment Type: | L/C,T/T,D/P,Money Gram,Western Union |

|---|---|

| Terms of Trade: | FOB,CIF,EXW,CIP |

| Min. Order: | 3000 Piece/Pieces |

| Delivery Time: | 7-30 Days |

| Packaging: | Foam protecter box ,inner box ,then into the standard export carton |

|---|---|

| Productivity: | 5000TON/Y |

| Brand: | Besten |

| Transportation: | Ocean,Land,Air,by train |

| Place of Origin: | Zhejiang |

| Supply Ability: | 5000TON/Y |

| Certificate: | ISO14001/OHSAS18001/ IATF16949 this year)/ REACH /ROHS |

| HS Code: | 8505111000 |

| Port: | ningbo ,shanghai,other workable ports |

Click on the follow link to find out more information: https://www.bestenmagnets.com/ferrite-magnets/

Company Info

- Company Name: Ningbo Besten Magnet Co., Ltd.

- Representative: Timo Sun

- Product/Service: Arc Sintered NdFeB Magnets , Sintered NdFeB Magnets , Bonded NdFeB Magnets , AlNiCo Magnets , SmCo Magnets , Magnetic Assembly

- Capital (Million US $): 1000,000RMB

- Year Established: 2018

- Total Annual Sales Volume (Million US $): Above US$100 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): Above US$100 Million

- No. of Production Lines: 15

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Xiepu Industry Park,Ningbo,China

- Contact Person: Mr. Timo Sun

- Tel: 86-0574-86680360

Email to this supplier

Premium Related Products

Other Products

Hot Products

Outdoor Rechargeable Lamp, Portable LED LightResin Craft, Resin Horse for Office DecorationFactory Sale 360 Degree Rotation Car Phone Holder, Magnetic Mobile Phone Support HolderLuxury Handmade Custom Logo Printed Paper Jewelry/Ring/Necklace Gift BoxCustomized Logo Business Card Holder /Credit Card Holder for GiftFashionable Card Case, High Quality Credit Card Holder, Credit Card WalletCustom Design Wine Bottle Neck Tag, Wine TagWholesale Fashion Silver Jewelry Box, Sweet Heart Metal Jewelry BoxAluminum Business Card Holder, Name Card HolderHigh Quality Purse Hook, Purse Hook for BagColorful Metal Notepad Holder, Memo Pad HolderPainting Stainless Steel Name Card Box (BS-S-002)Hand Push Type Business Card Holder, Soft Enamel Business Card HolderPU Business Card Holder for Gifts (BS-L-063)Heart of Gold Bottle StopperGold Plating Pig Wine Pourer with FDA/SGS Approval